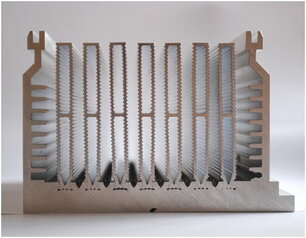

Crimping fins in a heat sink

Crimped fins heat sink

Crimped fin heat sinks are generally geared towards physically large applications that require moderate performance. Crimped fin heat sinks are made by crimping (pressing) or pressing individual fins of metal to a base. The bonding of the fins to the base plate is be done by pressing and deformation. The main advantage to this type of heat sink is it can be used for large applications. The main drawback is manufacturing process isn’t automated on the scale of stamped, extruded, or folded fin heat sinks, resulting in a higher cost for crimping fins into a heat sink

Crimped Fin heatsink is a heatsink in which copper or aluminum heat-dissipating fins are mechanically bonded onto a base plate of copper or aluminum, thereby being provided with high performance because the fins can be densely arranged. The heatsink has been developed to deal with thermal solutions where integral heatsinks made of aluminum extrusions conventionally in use are not applicable.

The aluminum extrusion-based integral heatsink is manufactured by extruding an aluminum extrusion to the shape of the heatsink itself and cutting it to a specified length, thus featuring the lowest manufacturing cost. Due to the geometrical constraints of the extrusion dies, however, the heatsink has a fin configuration limitation of 0.5 mm in fin thickness and 2.3 mm in fin pitch. To increase the heat transfer area, we have no choice but to manufacture the base plate and the fin separately, then bonding them by some means.

The bonding methods come in two ways, namely brazing including soldering and mechanical bonding like crimping or swaging. The Crimped Fin heatsink is manufactured by a mechanical method such that the base plate is grooved, fins are inserted into the grooves and are fixed by mechanically deforming both sides of the grooves. The fins are fixed with force and metal deformation with a pressing machine.

Pressed Fin assemblies or crimped fins assembly are ideal for applications involving high thermal and mechanical clamping loads. This product series is manufactured by pressing thick serrated fins into the base, where the fins are securely fixed to the base by a cold weld joint that takes place during the insertion process due to the unique design of the fin base and baseplate slot which alleviates the need for any bond agent. This type of heatsink is targeted for applications with high air velocities with the capability to overcome high pressure drops due to the high fin density and serrated surface area of the fin configuration.