What Can today be produced on a fin skiving machine?

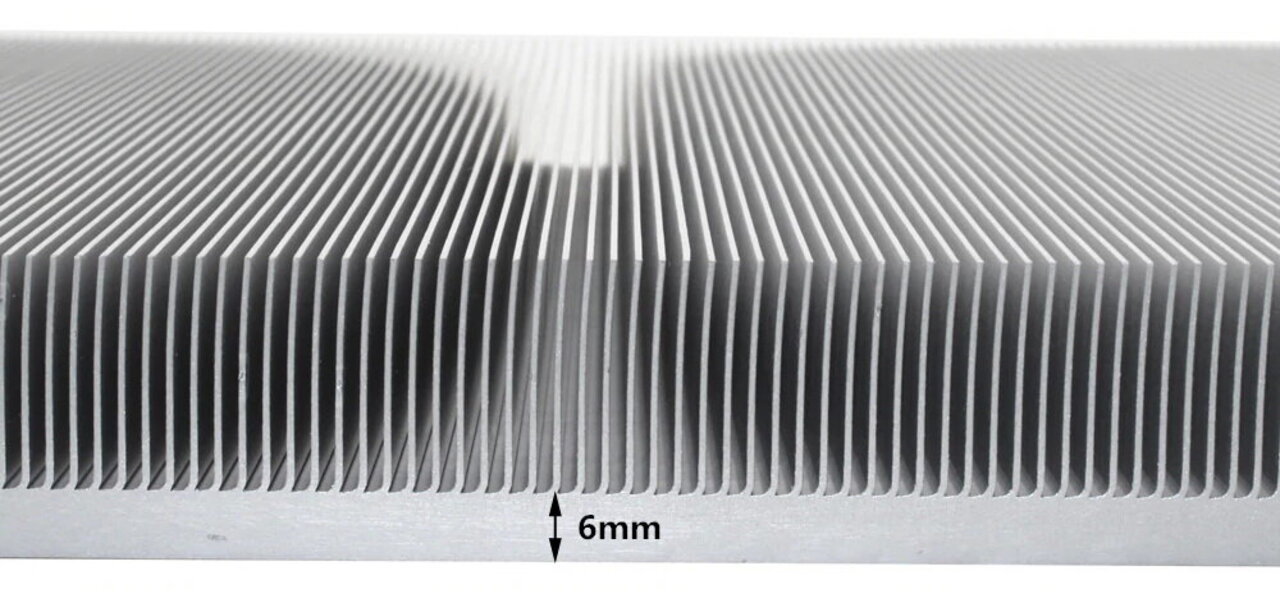

Skiving is a process in which the cooling fins are carved from a single aluminum or copper block, with no interruption in the connection between the fins and the heat sink. This produces high-density heat sinks with very fine and high fins that are directly connected with the heat sink base. The process also ensures high specific power density.

Our new range of skiving machine now allows you to manufacture high-performance heat sinks with even higher and finer fins, while reducing the distance between the single fins.

The following maximum parameters for copper or aluminum heat sinks can be achieved with the machine:

Fin thickness: Al: 0.1 – 2.0 mm; Cu: 008 mm – 2.0 mm

Length of heat sink: Al and Cu: 10 mm – 3000 mm

Width of heat sink: Al and Cu: 10 mm – 900 mm

Fin height: Al and Cu: 1 mm – 180 mm

Distance between fin centers: Al: 0.2 –12 mm; Cu: 0.16 mm – 12 mm.

The new dimensions represent a substantial improvement over previous capabilities. If required, skived fin heat sinks can also be CNC machined to improve the flow path through different fin orientations, therefore fulfilling more stringent cooling requirements.