Global outlook of the skived fin heat sink market !

Skived fin heat sinks are widely used in various industries, including electronics, telecommunications, aerospace, and automotive, to dissipate heat generated by electronic components.

Emerging trends in the global skived fin heat sink market include the increasing adoption of lightweight materials such as aluminum to improve thermal efficiency, as well as the growing demand for miniaturization in electronic devices. There is also a rising focus on the development of high-performance heat sinks with enhanced heat dissipation capabilities to cater to the growing demand for advanced cooling solutions. Additionally, the market is witnessing the integration of advanced technologies like additive manufacturing and liquid cooling systems to further improve heat sink performance. These trends indicate a shift towards more efficient and compact heat sink solutions to meet the evolving needs of various industries such as electronics, automotive, and telecommunications.

The current outlook of the skived fin heat sink market is promising. With the increasing demand for advanced electronic devices and the need for effective thermal management, the market for skived fin heat sinks is expected to witness significant growth. These heat sinks offer improved heat dissipation efficiency and compact size, making them a preferred choice in the electronic industry.

Additionally, the growing adoption of power electronics and the increasing popularity of electric vehicles are driving the demand for skived fin heat sinks. These heat sinks are capable of handling high heat loads and provide better thermal conductivity, making them suitable for power electronic devices used in various applications.

Furthermore, the increasing focus on energy efficiency and the implementation of stringent regulations regarding the thermal management of electronic devices are further expected to drive the growth of the skived fin heat sink market.

Heat Sink Market Dynamics

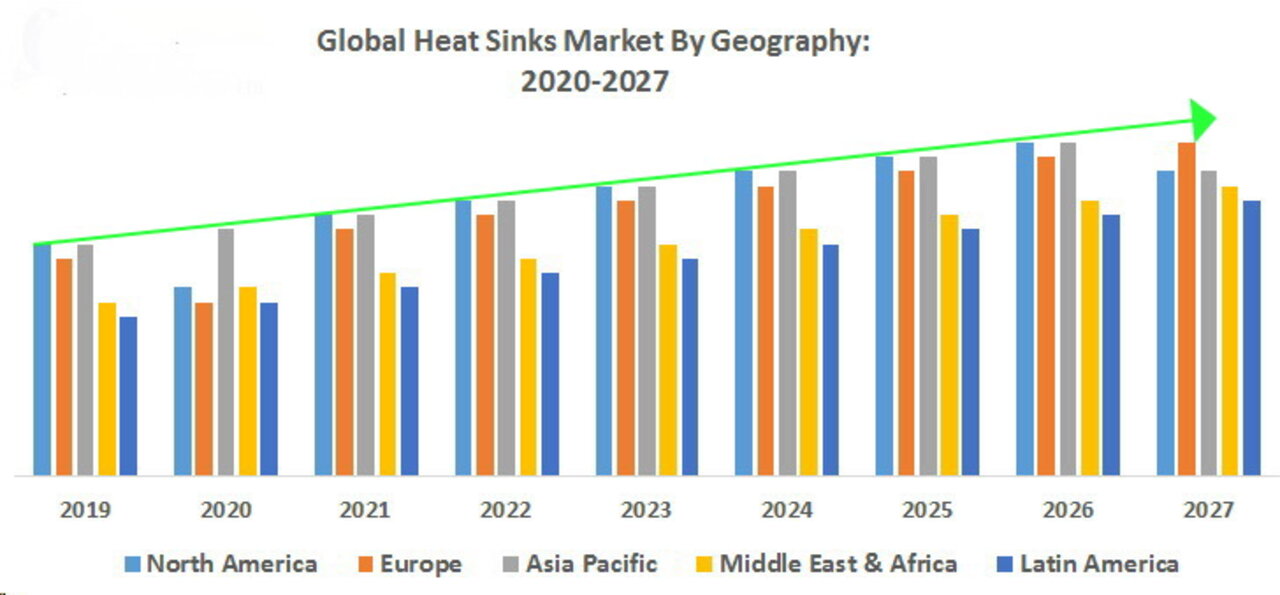

Estimated growth of 8.5% per year next years

The global thermal management market is estimated to be € 12.8 billion by 2025 (forecast year) from € 8.8 billion in 2020 (estimated year), at a CAGR of 8.2% between 2020 to 2025.

The growth of the thermal management market is fueled by rising demand for effective thermal management solutions and systems for use in consumer electronics, increasing use of electronic devices in different end-use industries, and ongoing radical miniaturization of electronic. Thermally efficient and durable heat exchangers are the major drivers which help in surging the growth of heat sinks market. Increased power and decreased size of heat sinks will add new opportunities for this market in the coming years.

The growth of the heatsink market is mostly attributed to the rising demand for high-power semiconducting devices and Optoelectronic products. Growing adoption of heatsink in order to enhance product performance and maintain thermal stability is further expected to raise drastically more performant product demand like skived fin heatsinks.

Choosing the right industrial heat sink is the key to optimize your product performance.

Selection considerations depend on space availability, ambient temperature, transient conditions, overload capacity, and whether the application depends on convective or forced air cooling methods.

High aspect ratio heat sinks

High performance heat sinks

There are many suppliers of heatsinks but very few can manufacture the high aspect ratio heatsinks needed for the power electronics market. There is a growing need for these high performance heatsinks with the recent adoption of silicon carbide (SiC) power devices.

We do supply the machinery to produce the high aspect ratio heat sinks!

Electronics today are growing exponentially smarter and more powerful as they become smaller and more prevalent leading to increased power demands and a greater need for better thermal management. Dissipating increased heat is often the biggest barrier to optimized functionality and product success. To maintain performance and safety, extend device lifetimes, ensure customer satisfaction, and improve reliability, this additional heat must be removed.

Through consistent innovation in engineering and manufacturing, Profimach provides the best optimized, cost-efficient production solution providing you with the Very best production technology for heat sink Production advanced cooling technologies.

By choosing, integrating, or developing our fin skiving technology, whether it be a two phased, air cooled, or liquid system, Profimach delivers a production tool that offers thermal management solutions that can increase power, improve functionality and reliability, and reduce the cost and size of your applications.

Profimach's fin skiving production solutions extend the traditional and advanced air cooling and liquid cooling systems and heat exchangers, to more advanced and higher performant conduction cooling and much better heat transfer. Skived fin technology can be applied on the cutting edge of immersion cooling boiler plates, ultra thin vapor chambers, thermosiphons, complex heat pipe assemblies for high heat flux applications, and much more.

Skiving heat sinks are involved in many fields (such as large servers, computers, frequency converters, automobiles, refrigerators, large machines, medical, communications, radio and television equipment, military industry, etc.).

Skiving fin technology originated from high tech mechanical industry, mainly used in aerospace, military, precision machine tools, electronic equipment and other sophisticated or high-precision industries. With the progress of science and technology and processing technology, Skiving fin technology has been gradually transferred to civilian use and applied to IT and industrial heat sink manufacturing industry.

The principle is a whole piece of copper or aluminum according to needs, with a professional skived fin machine cut out the standard spacing of heat sink fin, because of the use of precise skived fin technology, integrated manufacturing, heat transfer medium stability, heat sink thickness is greatly reduced, under the same conditions the heat transfer effect is till 200% of the traditional heat sink. Thus can greatly improve the heat transfer efficiency and extend the service life of heating components.