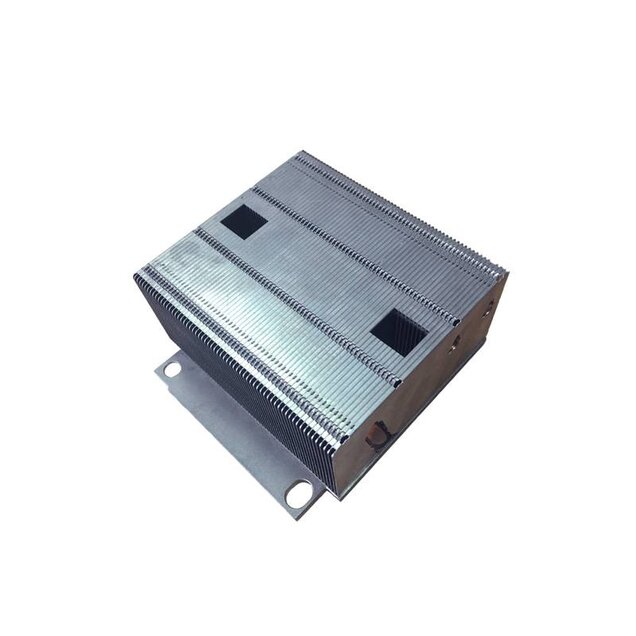

Stacked fin heat sink

Stacked fin also know as snapped fin or zipper fin

Stacked fin heat sink is made by using a high pressure to pressing special structure single profile, multiple profiles together into a complete heat sink. Stacked fin (also know as snapped fin or zipper fin) heat sinks are manufactured by stamping sheets of rolled aluminum or copper into a tightly formed array of fins. The character is neat on a metal plate with multiple parallel intervals are arranged on the convex groove and the groove, and the groove under each convex slot on the top and bottom of each one vertical bending forming one cant, cant make the groove under a heat sink in a heat sink on convex slot cant agree with each other, so that the multiple heat sink stacked together to form a heat dissipation module. With large heat dissipation area and simple assembly, convenient and fast. Stacked fin solutions offer better performance when compared to typical extrusion heat sink, due to thinner fin profiles leading to higher surface area and lower pressure drop. The stacked fin heat sink is often used in machines that need heat dissipation from both sides. From the appearance, both sides are cooling base plate, the heat sink fins in the middle, heat from both sides through cooling base plate to the central fins for heat dissipation.

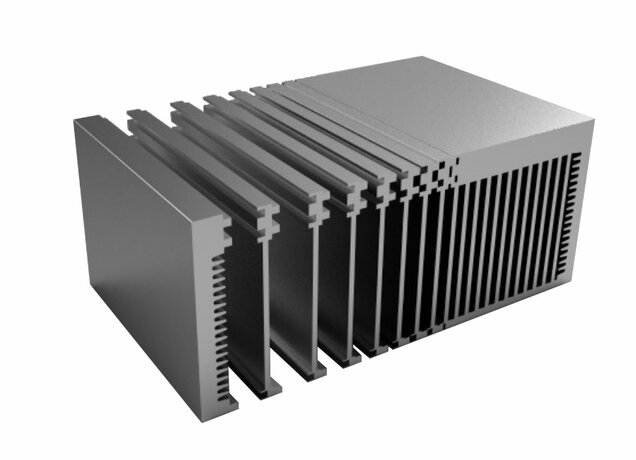

Stacked Fins or zipped fins

The stacked fins heat sink fin is achieved using conformed metal sheets stacked together in a direction to produce the stacked fins array. Stacked fins can be manufactured with higher aspect ratios. This stacked fins array creates a huge amount of surface area to dissipate the heat while maintaining good airflow through the heat sink. Stacked fins heat sink also conveys the benefit of reducing the cost and lead-time. Compare to folded fin heat sinks, stacked fins heat sink has lower tooling cost and are faster fabricated and assembled. This makes the stacked fins heat sink an attractive alternative particularly in smaller lot size manufacturing. Pipe-thru-fin is a typical example of stacked fins in heat pipe assembly.

Stacked heat sink

Stacked heat sinks are formed by using a high pressure to press single fins, multiple fins, and single extrusions together into a stacked heat sink. This type of stacked fin heats which are formed by press-fit approach can realize a cooling structure that has both top and bottom base plates for mounting power devices. No interface material is required for assembly when using this technique and it has the benefits of low development cost, high flexibility in forming heat sinks with different width and structures so that it is highly universal. This technique has been widely used in the cooling of high power devices such as power inverters and transformers, generators, etc. Stacked heat sinks have advantages such as increasing cooling area while forming a closed passage at the same time so as to achieve higher thermal performance, no restriction on it volume, higher strength, lower manufacturing cost, easier installation and maintenance, longer service life, etc.