4G -> 5G

As we now move from 4G to 5G, we continue to be an integral part of the eco-system that will revolutionaize the future of connectivity. We look forward to being a part of the future of connected and intelligent services to serve consumers, enterprises and take artificial intellgience and internet of things to the next level.

We provide a line-up of machines and technologies for various outdoor and indoor cooling sub-applications including high efficient heat sink cooling of: Radio Unit, Baseband Unit, Cabinet & Enclosure, and Backhaul Optical Module.

RADIO UNIT

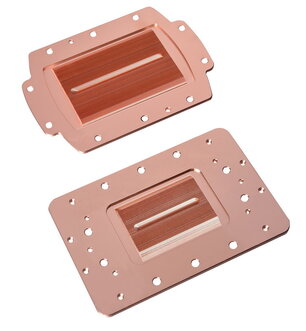

Taking the key factors into consideration that affect thermal performance, outdoor requirements, weight and cost-effectiveness, we provide high efficient thermal solutions for frame heat sinks, PA plates and modules. As new standards emerge like antenna arrays integrated into the radio access, we are ready to provide thermal fin heat sinks as enhanced natural convection cooling solution to significantly improve heat dissipation efficiency.

BASEBAND UNIT

Both indoor and outdoor baseband units are required to be more compact while the chipsets and FPGAs evolve toward higher power density. We provide total heat sink solutions production equipment to meet surging thermal requirements. At the join-design stage, we take into account overall forced convection environment to proactively propose to our customers for optimal design.

The development of 5G networks including infrastructures, edging computers and end-market devices will significantly scale up global demand for heat-sink solutions in 2020 and beyond.

5G Thermal Solutions

5G cooling design and manufacturing solution

With 5G footsteps getting closer, the data traffic demand continues to soar, network load increased significantly, the number of communication base station is also more and more, because of communication station to have certain requirements in sealing, and transmitting equipment in operation process is easy to generate a lot of heat, the base station power consumption and equipment heat dissipation problems become increasingly serious, so need to heat dissipation, communication base station existing technology mainly adopts air conditioning refrigeration for cooling. Although it can achieve the cooling operation, but the area is larger also, large energy consumption and easy into the dust and, not conducive to the maintenance of equipment, so the applicability and practicability is restricted. We provide 5G heat sink cooling design and manufacturing solutions to support higher power load in a fully integrated system, prolong the life of the sensitivity and 5G equipment, our skived fin advanced cooling technology is able to meet challenging environmental requirements, including integrated heat pipe, liquid cold plate, vapor champers, custom skived fin , base station shell, etc.

5G heat sink types

With our fin skiving technology you can design and customize various types of 5g heat sink. It's mainly 5G base station heat sink, server heat sink, chip heat sink and processor heat sink on 5G equipment.

5G base station heat sink

Reliability design is an important design link in communication system design, and the heat dissipation effect of equipment, especially the heat dissipation design of high power equipment, has a crucial influence on the reliability of equipment.

When data is moving at these very high speeds, the distances have to be reduced, so people have to have more antennas and data centres at the point of content acquisition. Basically every data lamppost has to have an antenna. In other words, the data channel must get shorter as it gets wider.

Base station is a radio transceiver that transmits information between the terminal and the mobile communication exchange center in a certain radio coverage area. It is an important information hub of the wireless communication system. At present, a base station is developing in the direction of large capacity, higher power and higher integration, and the heat dissipation per unit volume is also increasing, while the volume is getting smaller. The thermal design of base station has become an increasingly important problem in the design of base station complete machine. Normally, when the temperature exceeds a certain value, the failure rate of electronic devices increases exponentially with the increase of temperature. Improper cooling system is one of the main reasons for the decrease of the reliability of the electronic devices. 20% of the failures of electronic devices are caused by high temperature.

Nowadays, the arrival of 5G requires more powerful severs to support the successful information transmission. 5G network signals have higher reliability and lower delay, which can meet the specific needs of intelligent manufacturing, automatic driving and other industries. For 5G network infrastructure construction pattern to transform to the intensive, miniaturization, intelligent, traditional large base stations have been difficult to meet the demand of the construction of the 5G base station. Base station heat sink must keep cool in the operation process, multiple fever semiconductor components such as CPU, chips must be closely together to achieve the best electrical properties, but also to cooling under this compact configuration.

The high capacity 5G base station market favors low cost and high heat dissipation requirements, requiring the use of high performant heat sinks, cooling devices, heat pipes or thermal interface materials (TIM), rather than using liquids that require electricity or forced liquids. Our fin skiving technology is able to dissipate these high heat fluxes much better in combination with using heat pipes with high thermal conductivity, providing a safe operating environment.

5G Server heat sink

Nowadays, the upcoming 5G requires more powerful servers to support the successful information transmission. 5G network signals have higher reliability and lower delay, which can meet the specific needs of intelligent manufacturing, automatic driving and other industries. Therefore, as you you also need to cool the server, we can provided a fin-skived heat transfert liquid cool solution for 5G servers in combination with skived fin heat sinks. The working principle of this liquid-cooled cooling method is to directly cool the electronic equipment by using heat pipes equipped with liquid cooling . After the coolant absorbs heat, the liquid temperature rises and can be used for heating. Heat can also be distributed to the outdoor air, cooling liquid temperature, and then send the cooling liquid to the heat pipe of electronic equipment. Since the main benefit of the water cooling plate to the server is to take away the heat nearby, it can have a high energy saving effect, at the same time, greatly improve the high power density to reduce the size of the server, reduce the fan noise, and easily realize the heat recovery and other benefits. The main technical feature of the water cooled heat sink is that the main board of the server is installed in pairs on the two outer sides of the heat sink, which flows through the cooling water with lower temperature to take away heat. High heating elements, such as CPU and north-south bridge chipset, are installed close to the cooling water in the heat sink and use micro fin skiving technology to transfer the heat optimal to the cooling circuit, so that the heat generated is carried away by the cooling water in the heat sink.

5G processor heat sink

We adopt or micro fin skiving technology in the latest liquid cooling technology to deal with the 5G heat dissipation of CPU system.The water cooling system is composed of water ice, circulating coolant, water pump, corresponding pipes and fin skived heat exchangers. Water cooling plate are usually copper or aluminum plate, which have excellent heat transfer performance. Vacuum pipes are reserved inside these metal blocks to store coolant and circulate it. The water cooling plate and the CPU can directly contact and absorb the heat generated by the CPU. Through the forced action of the pump, the circulating coolant flows repeatedly in the flow pipeline or thru the fin-skived heat exchange plate of the water cooling block, so as to take away the absorbed CPU heat and turn the high temperature into the low temperature, so as to achieve the purpose of cooling the CPU of the 5G equipment. Heat can be transferred out through the fin skived heat exchanger into the heat sink, heat sink surface area, heat dissipation effect is good, the fan in the form of strong convection heat into the air.The advantages of this water-cooled heat dissipation mode are good heat dissipation effect and low noise, which are widely used in some large service stations.

5g chip heat sink

In order to meet the requirements of the reliability of thermal equipment of electronic equipment, control the chip temperature within a certain range and reduce the failure rate of equipment, the thermal design of high power chips must be carried out. We do have rich experience in chip cooling by fin-skived heat exchangers

Chip heat is passed to the high performance fin skived heat sink by thermal conductive materials, followed by heat dissipation pathways into the surrounding air with help of our fin skived technology.